13402527395

一、 Design requirements for medical gas system

1. Non medical equipment shall not be used for medical purposes

2. Medical equipment shall be set in places far away from the emission of pollutants limited by medical air

3. The medical air source shall be able to supply air continuously in a single fault state

4. Medical air storage tanks shall be made of corrosion-resistant materials

5. The medical air compressor system has man-machine interface display and on-line monitoring of key data

6. Automatic linkage control of the whole set of medical gas equipment, one key start and stop, power failure to restore the self starting function, and dual unit combined gas supply mode

Pressure swing adsorption (PSA) is a new gas adsorption and separation technology. It is realized according to the different adsorption capacity or adsorption rate of different components in the mixed gas on the adsorbent at constant temperature and the different adsorption capacity of the same component on the adsorbent at different pressures. Due to the cyclic operation of pressure fluctuation, the strongly adsorbed components desorb at low partial pressure and the adsorbent can be regenerated. It is called pressure swing adsorption.

The amount of adsorbate adsorbed by the adsorbent increases with the increase of pressure and decreases with the decrease of pressure. At the same time, the adsorbed gas is released during decompression (reducing to atmospheric pressure or vacuumizing) to regenerate the adsorbent. The adsorbent can be regenerated without heat from the outside. Therefore, PSA is known as isothermal adsorption, also known as non thermal regeneration adsorption.

1. Compact structure design and small floor area.

2. Efficient and energy-saving process design, scientific equipment configuration and combination, high oxygen production efficiency

3. Stable and reliable automatic control design, high degree of automation, convenient equipment operation and unattended

4. The digital touch automatic control system can adjust the flow, purity and pressure of product oxygen according to needs

5. PSA pressure swing adsorption oxygen production principle is adopted, with fast oxygen production speed, and qualified oxygen can be produced within 30 minutes

6. The equipment has stable operation, low failure rate and less maintenance

7. The equipment works under low voltage, safe and reliable

8. The equipment has low operation cost, low noise and only needs to consume electric energy. It is an environmental protection product

四、System components

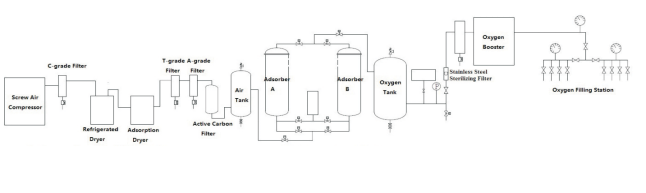

The oxygen generation system of medical molecular sieve center is mainly composed of high-efficiency screw air compressor, main circuit filter, freeze dryer, multi-stage precision filter, air storage tank, oxygen generation host, oxygen storage tank, sterilization filter, oxygen purity analyzer, oxygen flowmeter, electrical control system, pipeline system, etc.

Medical oxygen generator with filling legend