The medical gas equipment management system is connected with the oxygen generator equipment through remote monitoring software, central console, Ethernet and forms a set of overall remote monitoring solution, which aims to reduce the operation and maintenance cost and improve the operation and maintenance efficiency. It integrates real-time data display, data storage and printing, operation condition prediction, alarm information generation A new intelligent and information-based management system integrating various functions such as equipment scientific management.

13402527395

The medical gas equipment management system is connected with the oxygen generator equipment through remote monitoring software, central console, Ethernet and forms a set of overall remote monitoring solution, which aims to reduce the operation and maintenance cost and improve the operation and maintenance efficiency. It integrates real-time data display, data storage and printing, operation condition prediction, alarm information generation A new intelligent and information-based management system integrating various functions such as equipment scientific management.

The whole machine adopts automatic intelligent control system

1. Intelligent joint control of medical oxygen generating unit

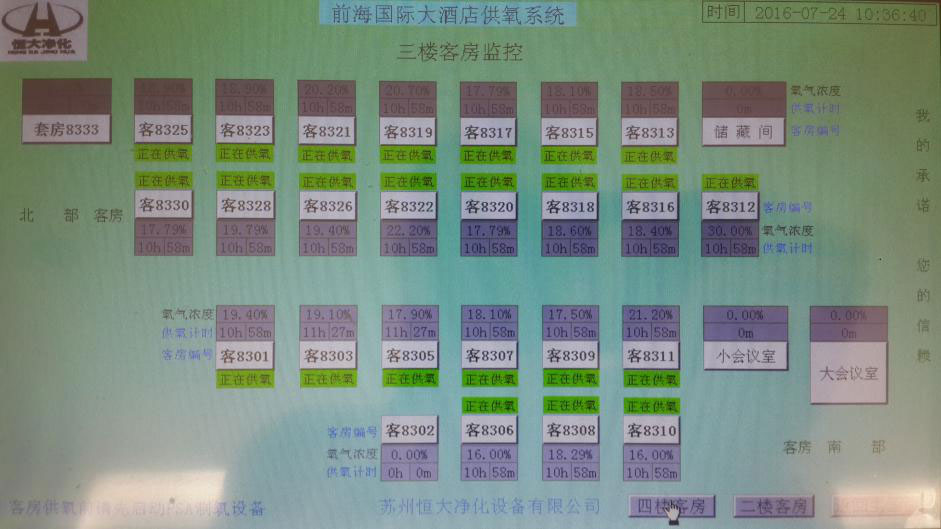

(example of oxygen supply terminal management system)

Real time monitoring: it can monitor the flow, pressure, gas purity, dew point, ambient temperature and humidity of oxygen in real time for analysis and centralized display on the monitoring host.

Remote monitoring: the control system reserves a remote communication interface, which can be connected through the network, and the monitoring host can

Remotely monitor the parameters and operation of gas supply equipment to realize unattended.

Real time alarm: when the oxygen parameters and gas supply equipment are abnormal, the equipment alarm and the monitoring host alarm at the same time. The alarm information is clear. The abnormal alarm point can be displayed directly on the touch screen to remind the staff to find the fault in time and accurately, shorten the maintenance time and provide gas safety.

Intelligent management: there is a monitoring host to collect, control and process relevant data, form a perfect data library for all operating parameters, and have the functions of query and search for operating parameters and alarm data, so as to provide a theoretical basis for oxygen terminal management.

Advantages of medical molecular sieve oxygen generator::

1.Using air as raw material, oxygen is directly extracted from air by pressure swing adsorption principle. This physical separation method only consumes electric energy, and the oxygen produced is green, safe, environmental friendly and economical;

2. Absorbing the advantages of foreign oxygen generator manufacturing technology, and after many modifications and upgrades by our technicians, we have developed a variety of breakthrough technologies in the aspects of intelligent linkage control of the main body of the oxygen generator, application of molecular sieve, equipment noise, air treatment, unqualified oxygen recovery and operation loss, so as to ensure the safe and stable operation of the oxygen generator system;

3. Freezing air dryer and adsorption air dryer are adopted, which can make the dew point of treated compressed air less than - 40 ℃ and up to - 70 ℃, so as to improve the service life of molecular sieve and ensure the oxygen production quality of oxygen generator;

4. The equipment adopts a full set of German Siemens PLC automatic control system, with audible and visual alarm devices such as oxygen purity, outlet pressure, high and low pressure switch, thermal overload, system emergency stop, high-precision mass flowmeter, one key start and stop, whole machine joint control, incoming automatic start, dual unit combined oxygen supply mode, etc

5. The molecular sieve does not need regeneration treatment within its service life;

6. The gas production speed is fast. Qualified oxygen can be produced within 30 minutes after the first startup and 10 minutes after the second startup

7. The placement of the whole set of equipment in the machine room can be designed according to the user's requirements, with beautiful appearance and small floor area;

8. It has a perfect after-sales service system and after-sales personnel to provide users with high-tech products and perfect services.